PCB Development

Most conventional PCB design workflows begin with discrete component prototyping on a breadboard, employing a granular setup to evaluate circuit behavior. The finalized schematics are typically derived through iterative 'trial-and-error' cycles.

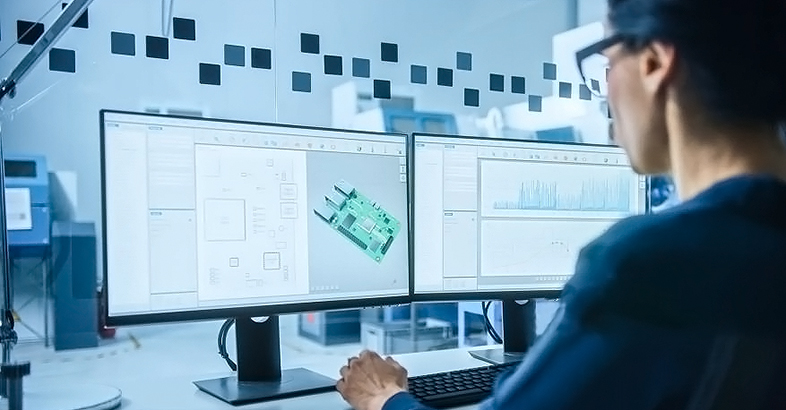

Present design methodologies allow for direct translation of theoretical schematics into preliminary PCB layouts, which are incrementally optimized within ECAD environments. These platforms offer integrated simulation and verification tools, effectively replacing the need for discrete hardware testing by validating circuit integrity and performance virtually.

Despite the ECAD simulation engines, many engineers still favor breadboard prototyping, convinced that this hands-on phase yields the most reliable empirical data and practical insights to improve the accuracy and robustness of the final schematic design.

Our developers and engineers leverage Altium™ Designer, an industry-trusted ECAD platform known for its power, precision and flexibility. This advanced design environment enables us to move quickly from concept to production, minimizing development cycles while maintaining the highest standards of quality. With integrated simulation, layout, and project management tools, Altium™ Designer plays a key role in helping us craft cutting-edge audio hardware with efficiency and confidence.

"I’ve already created a concept design in KiCAD, UltiBoard, or MultiSIM - is that an issue"? Absolutely not! We can easily convert all provided ECAD file formats and extensions into Altium™ Designer. Regardless of the ECAD suite you’ve used, we can seamlessly integrate your concept into our development workflow. Additionally, if you'd prefer to continue working within your own ECAD environment, we can convert Altium™ Designer files back to your preferred format without any trouble.

Printed Circuit Boards (PCBs) have undergone significant advancements over the years. Today, they are essential to a wide variety of products that rely on electronics, from simple children’s toys to advanced, high-performance smartphones. These intricate boards are not created instantly; they are the result of a detailed and often time-consuming development process that takes place long before mass production.

The complete electronics design process includes:

█ 1. Requirements definition.

█ 2. Cost and time estimates.

█ 3. Design proposal, including cost and timescales.

█ 4. Project planning.

█ 5. Design specifications.

█ 6. Schematic design.

█ 7. PCB layout design.

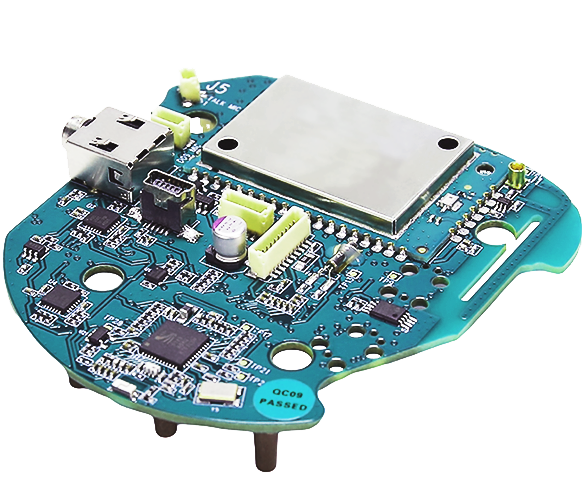

█ 8. Prototype fabrication.

█ 9. Environmental and functional testing.

█ 10. Preparation of production manual and Bill of Materials (BOM).

█ 11. Production oversight and management.

Once the electronic schematic is finalized and all design revisions are locked in, the PCB layout phase begins. Using Altium™ Designer, our engineers perform both pre-layout and post-layout simulations, along with thorough Design Rule Checks (DRCs) and Electrical Rule Checks (ERCs). These steps help ensure design integrity while proactively identifying potential issues with signal integrity or power distribution.

This iterative validation process reduces the risk of downstream failures and enables targeted optimizations that improve overall system reliability. However, it’s important to understand that the initial hardware build, commonly referred to as the Proto-0 board, primarily serves as a proof of concept. As such, it may reveal unforeseen performance issues or design limitations that necessitate further refinement.

Manufacturing the first version of a PCB doesn’t guarantee flawless operation. Before moving forward with a fully functional prototype (commonly referred to as Proto-0), the board must undergo thorough testing to uncover and address any

bugs

Origin of the term “bug”

The term “bug” was popularized in 1947 when engineers working on the

Harvard Mark II electromechanical computer discovered a moth trapped

in relay panel “F”, causing a malfunction. The incident was recorded

as the first actual case of a bug being found.

The word had already been used earlier by inventor Thomas Edison in

the 1870s to describe technical faults in electrical inventions. The

1947 event helped establish its modern meaning in electronics and

computing: a fault, glitch, or unexpected behavior in hardware or

software systems.

or performance issues.

At this stage, it's common to encounter software-related problems within the microprocessor or microcontroller. The Microcontroller Unit (MCU), often working alongside the embedded µProcessor, serves as the device’s "digital traffic controller", orchestrating interactions between key components such as memory, sensors, actuators, displays and switches. When issues arise within the µController, it often requires reprogramming.

To develop and debug (embedded) code our engineers use Visual Studio Code with compilers for C, C++, or C# (C-sharp), or alternatively, CodeFusion Studio™ when working in more specialized embedded audio environments. This development process involves a cycle of debugging, testing and evaluating changes, often repeated multiple times, to ensure not only correct system behavior but also consistent and reliable operation.

Following thorough functional testing, the design team evaluates whether the PCB meets the defined requirements for its intended application. Unlike broader stages of product development, where the PCB is just one part of the whole, this phase focuses specifically on the board’s integration within the final product, both electrically and mechanically.

Working closely with software developers and mechanical engineers, the team identifies and implements any necessary refinements. This ensures that all components, from connectors to power systems, operate cohesively and reliably. At this stage, the goal is to confirm that the PCB not only functions as intended but also fits precisely within the product’s mechanical design constraints.

Mechanical-electrical integration begins with adapting the PCB layout for its target enclosure, ensuring alignment with mechanical constraints and interface points. The cross-disciplinary team, comprising mechanical engineers, industrial designers and electronics developers, validates the board's functionality & compliance with all electrical and mechanical specifications after iterative revisions.

Once verified, mechanical parameters such as mounting points, clearances and connector positioning are fine-tuned for optimal enclosure fit. Subsequently, critical factors like mechanical stress, vibration resilience, and thermal distribution are analyzed through finite element simulations and real-world testing, ensuring reliable heat dissipation and long-term system stability.

More Specifics...

The full scope of PCB development for high-end audio and automation systems goes far beyond what we can explain on a single page. These designs often involve complex multilayer layouts, precise mixed-signal routing, careful power distribution, and stringent EMI control; all critical for maintaining audio fidelity and system stability. If you're interested in how we approach professional-grade hardware design, or want to discuss specific technical aspects, feel free to reach out by phone or email.

Measurable operational improvements

An analysis of the project results and underlying KPIs shows that 92% of our projects met their development timelines, an improvement compared to previous years. This indicates that the ongoing adjustments to process optimization and team integration are having a positive impact. We remain focused on further improving our working methods to ensure your product is delivered on schedule.

WITHIN DEADLINE

PROJECT TEAM

ENGINEERING