Manufacturing

The production phase of a developed design is fully overseen by our Project Management team. After completing the design and content of the Production Manual, and in consultation with all stakeholders, we begin the search for a reputable factory to carry out the manufacturing of your product.

We leverage a robust international network of reputable OEMs and manufacturing partners across Western Europe and Asia. Drawing on our deep expertise in cross-regional production management, we are able to strategically align each product’s technical requirements with the most capable and specialized manufacturer for optimal results.

Our involvement extends beyond production. After manufacturing, we continue to provide support by creating and refining the necessary technical documentation. This includes product websites, promotional content, user and service manuals.

Once the prototype has successfully completed verification and validation testing, and the corresponding Prototype Build Instruction Manual has been finalized, the development team and engineers advances to the preparation of the Manufacturing (Production) Manual. This document constitutes a core element of the production documentation set and functions as the authoritative reference for large-scale manufacturing.

The Production Manual systematically details the end-to-end manufacturing process, encompassing but not limited to the following:

█ Process Flow Descriptions

A stepwise outline of all production stages, from PCB assembly and component soldering to final system integration and packaging.

█ Tooling and Fixtures

Specifications for required tools, test equipment, and custom-engineered jigs or fixtures developed by the team to ensure precision, repeatability and safety during assembly.

█ Assembly Procedures

Standard operating procedures (SOPs) and work instructions, supplemented with diagrams and exploded views, defining the correct sequence of tasks and acceptable tolerances.

█ Supplier and Sourcing Information

An approved vendor list (AVL) identifying qualified suppliers, their associated part numbers, and procurement requirements for all electronic, mechanical and packaging components.

█ Quality Control Measures

Integration of inspection checkpoints, in-circuit testing (ICT), and functional test procedures to guarantee compliance with performance specifications and regulatory requirements.

By consolidating this information into a structured framework, the Manufacturing (Production) Manual ensures that manufacturing can be conducted consistently, with controlled quality and in compliance with relevant standards (e.g., ISO 9001, IPC-A-610 for electronics assembly). Moreover, it enables seamless knowledge transfer from the design/development team to the manufacturing floor, supporting scalability from pilot runs to full-scale production.

The procedures documented in the Production Manual serve as the primary reference framework for subsequent production planning at the designated manufacturing facility. It is the manufacturer’s responsibility to interpret and implement these defined processes, such as machining, molding, casting, surface treatment, and assembly, within a structured, efficient and repeatable production workflow.

This translation from documented procedures to operational execution involves the development of detailed process plans, workstation layouts, and production schedules that align with volume requirements and resource constraints. Furthermore, the manufacturer must ensure that process optimization techniques (e.g., lean manufacturing, Six Sigma methodologies and Statistical Process Control) are applied to achieve scalability without compromising quality or compliance.

The overarching objective of this phase is to establish a production system capable of consistently meeting demand forecasts while ensuring that each unit conforms to defined specifications and tolerances. By doing so, production planning bridges the gap between engineering design intent and reliable high-volume manufacturing, thereby minimizing variability and risk across all production runs.

Following completion of production planning, the selected contract manufacturer initiates full-scale assembly of the product in accordance with the specifications defined in the Production Manual. During this phase, all designated electronic, mechanical, and structural components are procured, verified and integrated into the final assembly.

The assembly process is supported by a network of suppliers and sub-suppliers, who provide critical parts, subassemblies, and semi-finished products. Collectively, these entities constitute the supply chain infrastructure that enables reliable material flow into the assembly line. Effective coordination across this network is essential to ensure component quality, maintain traceability and mitigate risks related to delays or shortages.

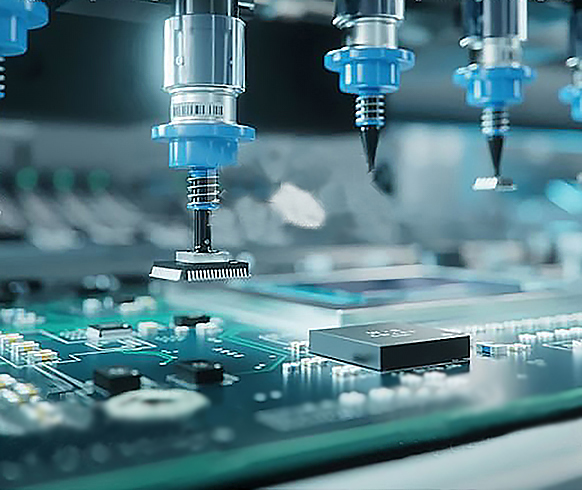

Within the assembly line itself, processes such as printed circuit board (PCB) population, mechanical integration, fastening, soldering and final system calibration are executed under controlled conditions. Quality control checkpoints are embedded throughout the workflow, ranging from incoming goods inspection to in-circuit testing (ICT), functional validation, and end-of-line verification, to guarantee that the assembled product meets all dimensional, performance and regulatory requirements.

Through the integration of robust supply chain management and disciplined assembly operations, the manufacturer ensures that the final product is constructed consistently, efficiently and in compliance with established engineering and quality standards (e.g., ISO 9001, IPC-A-610).

During production, Quality Assurance (QA) plays a critical role in ensuring that all semi-finished products, subassemblies, and components conform to the specifications established by both the development team and the client/stakeholder. QA managers conduct systematic inspections and testing at each stage of the process, from incoming goods verification through in-line monitoring and final product validation. These activities are guided by internationally recognized standards (e.g., ISO 9001, IPC-A-610 for electronics assembly, and ISO/IEC 17025 for calibration and testing), ensuring that only compliant materials and processes advance to subsequent stages of manufacturing.

In addition to in-process quality control, QA personnel implement process audits, statistical process control (SPC), and defect classification systems to continuously monitor production performance and identify potential non-conformities. This structured oversight minimizes variability, enhances reproducibility and guarantees that production output meets defined tolerances and regulatory requirements.

Oversight of the Asia-based OEM/manufacturing supply chain is provided by our partner in Hong Kong, YAHE (Jiaxing) Co. Ltd., who coordinates factory audits, supplier evaluations and pre-shipment inspections across the region. By conducting independent verification of manufacturing practices and ensuring adherence to client requirements, YAHE (Jiaxing) Co. Ltd. strengthens supplier accountability and provides an additional layer of assurance before products enter global distribution channels.

Upon completion of assembly, each unit undergoes a structured testing and validation protocol designed to verify compliance with functional, electrical and mechanical specifications.

1. Testing procedures typically include:

█ In-Circuit Testing (ICT)

Verification of solder joints, component placement and electrical continuity at the PCB level.

█ Functional Testing (FCT)

Validation of system-level performance under representative operating conditions, including load, signal integrity and power management.

█ Environmental and Reliability Testing (as applicable)

Stress testing under temperature, humidity, vibration or electromagnetic conditions to ensure conformity with regulatory and customer requirements.

█ End-of-Line (EOL) Inspection

Final inspection of fully assembled units, ensuring adherence to dimensional tolerances, cosmetic standards and product labeling.

The packaging process is designed not only to protect the product during handling and transportation but also to comply with industry standards for labeling, traceability and logistics.

2. Packaging specifications typically include:

█ Electrostatic Discharge (ESD) Protection

Use of anti-static bags, shielding materials and grounding measures for sensitive electronic assemblies.

█ Protective Packaging Materials

Foam inserts, custom-molded trays, or shock-absorbing enclosures to safeguard mechanical integrity.

█ Labeling and Traceability

Product identification labels, serial numbers, barcodes and regulatory markings (e.g., CE, FCC, UL, RoHS).

█ Export and Distribution Readiness

Outer carton specifications, palletization requirements and compliance with international shipping standards (e.g., ISTA, ISO 4180).

By integrating rigorous testing protocols with controlled packaging practices, manufacturers ensure that each unit delivered to the customer is fully functional, defect-free and protected against environmental or logistical risks. This phase completes the manufacturing cycle and prepares the product for distribution and market introduction.

Once the finished product has passed all quality assurance, testing, and packaging stages, it is released for outbound logistics. Products are transported from the manufacturer’s facility under conditions that ensure both safety and compliance, typically with full cargo insurance and documentation to mitigate financial and operational risks.

From the point of origin, shipments are directed to a designated logistics hub for regional or global distribution. At this stage, responsibility transitions to the Product Owner, who initiates and oversees the distribution process through contracted Third-Party Logistics (3PL) or Fourth-Party Logistics (4PL) providers. These providers act as key intermediaries, enabling efficient global supply chain operations by managing transportation, warehousing and fulfillment functions.

In addition to standard services such as storage, shipping, and receiving, many 3PL and 4PL providers offer value-added logistics services, including:

█ Order Fulfillment and E-Commerce Support

Processing, picking, packing and direct-to-customer delivery.

█ Returns Management (RMA)

Structured handling of product returns, exchanges and warranty claims.

█ Cross-Docking

Redistribution of goods with minimal storage time to accelerate delivery and reduce costs.

█ Kitting and Customization

Assembly of bundled product sets, promotional packaging, or market-specific configurations.

By leveraging these extended logistics services, organizations not only streamline international distribution but also strengthen after-sales support, ensuring that wholesale partners and end customers receive timely, reliable, and well-managed service. This final phase closes the production-to-market cycle and establishes the operational framework for ongoing supply chain sustainability.

More Specifics...

The full scope of manufacturing high-end audio and automation systems goes far beyond what we can explain on a single page. These processes involve precision assembly, rigorous quality control, specialized materials and acoustic tuning, all critical for ensuring reliability, longevity & pristine sound reproduction. If you're interested in how we approach professional-grade manufacturing or want to discuss specific production aspects, just reach out by phone or email.

Measurable operational improvements

An analysis of the project results and underlying KPIs shows that 92% of our projects met their development timelines, an improvement compared to previous years. This indicates that the ongoing adjustments to process optimization and team integration are having a positive impact. We remain focused on further improving our working methods to ensure your product is delivered on schedule.

WITHIN DEADLINE

PROJECT TEAM

ENGINEERING