Industrial / Mechanical Design

Within the discipline of Industrial and Mechanical Design, the field can be classified into four principal domains: Product Design, Transportation Design, Environmental Design and Interaction Design. Each domain is defined by its unique functional objectives and application-specific parameters. Operating within the Product Development sector, our Industrial and Mechanical Designers are responsible for translating theoretical performance requirements and design intents into fully realized physical products through a systematic and engineering-driven approach.

This end-to-end process enables the development of physical products optimized for mass production, systematically integrating design innovation with engineering rigor to define form, function and feature sets that meet market requirements. On this page, we detail the core technical and design methodologies employed by our engineering and design teams.

In the intricate world of product development, where innovation drives progress, two key disciplines, Industrial Design and Mechanical Design, play a pivotal role. Though they may appear distinct, these fields work hand-in-hand to shape the products we use every day. This in depth explanation explores the fundamental differences between the two disciplines, illustrating how they collaborate to strike the perfect balance between aesthetics and functionality, supported by real-world examples.

The design of certain products presents considerable challenges, not only because of their technical complexity, often necessitating the integration of multiple engineering disciplines, but also due to the centrality of aesthetic considerations. The automobile exemplifies such a product, functioning simultaneously as a technological artifact and a cultural design statement, regardless of whether it is powered by an internal combustion or an electric engine.

The automotive industry constitutes a distinctive convergence of technical and creative domains, engaging industrial designers, mechanical engineers, electrical engineers and electronics specialists. Owing to the significance of visual form, substantial effort is directed toward establishing a balance between aesthetic appeal and technological performance. Within this context, aesthetic priorities frequently guide the design process, yet must be reconciled with functional imperatives.

Moreover, the aesthetic character of a product is inseparable from its typology, intended function and target demographic. The client exerts a particularly influential role in this regard, shaping formal outcomes through brand identity, market positioning and broader corporate strategy. Consequently, product aesthetics emerge not solely from technical or artistic decisions, but from a complex negotiation among functional requirements, brand design traditions and institutional objectives.

The industrial and mechanical design process is commonly conceptualized as a structured, iterative methodology encompassing problem definition, concept generation, solution evaluation and selection, prototyping and validation through testing. This framework aligns with established models of engineering design methodology, which emphasize the integration of creativity, systematic analysis and manufacturability considerations.

█ Defining the problem

The process commences with the explicit formulation of the design problem, often referred to as the “problem space". Here, designers and engineers delineate functional requirements, performance targets and contextual constraints. Defining the problem rigorously is critical, as research in design cognition indicates that problem framing directly influences the quality and innovativeness of resulting solutions. Examples of such challenges may include reducing the structural mass of a housing component while maintaining durability or developing a mechatronic subsystem that leverages advancements in sensor integration.

█ Generating concepts

Once the problem is formalized, the focus shifts to the divergent phase of concept generation. Techniques such as brainstorming, morphological analysis, and early-stage computational modeling are employed to produce a broad solution set. Literature on design creativity stresses the importance of this stage in balancing divergent thinking with feasibility constraints. Concepts are typically evaluated not only for their technical merit but also for their alignment with cost, environmental sustainability and manufacturability.

█ Selecting the best solution

The convergent phase involves systematic evaluation of candidate concepts. Multi-criteria decision-making methods, including weighted decision matrices and analytic hierarchy processes, are frequently employed to assess feasibility, risk and scalability. This stage reflects the necessity of bridging conceptual design with production realities, ensuring that the chosen solution satisfies both engineering and economic requirements.

█ Prototyping

Prototyping represents a critical transitional phase between conceptual and detailed design. Early prototypes may take the form of low-fidelity models or digital simulations, gradually evolving into high-fidelity, production-ready representations. Empirical research highlights prototyping as a means of both validation and knowledge generation, enabling designers to iteratively refine their assumptions.

█ Testing

Testing integrates advanced computational tools such as mechanical computer-aided design (MCAD) and finite element analysis (FEA) to evaluate prototypes under simulated real-world conditions. These digital environments allow for stress testing, material comparisons, and performance optimization prior to physical fabrication. By reducing reliance on physical prototyping in early stages, simulation-based testing supports cost efficiency and accelerates the design cycle.

Taken together, this iterative methodology ensures the development of products that conform to rigorous performance specifications while remaining manufacturable at scale. Throughout the process, the mechanical designer functions as a critical mediator between creative ideation and industrial feasibility, embodying the dual role of innovator and systems integrator.

Once the design has been finalized and approved for implementation, the next phase involves developing a prototype. Prototyping represents a crucial bridge between conceptual design and full-scale production, allowing individual components to be integrated into a cohesive system. This stage provides valuable insights into the structural and functional characteristics of the final product.

The prototyping process can be divided into several key phases:

█ Component integration

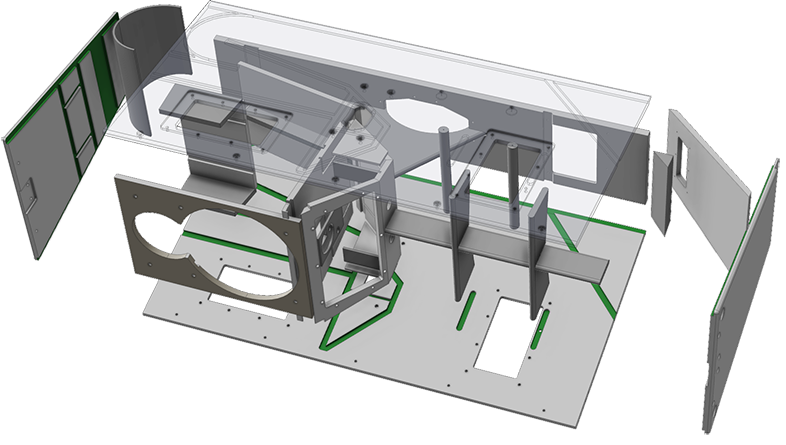

Systematic assembly of finalized design elements into a unified prototype, ensuring consistency and compatibility across mechanical, electronic, and structural subsystems.

█ Material selection

Identification of materials that accurately reflect the product’s functional, mechanical, and aesthetic requirements, while balancing durability, manufacturability, and cost-effectiveness.

█ Fabrication (3D printing / machining)

Implementation of rapid prototyping and manufacturing techniques—such as additive manufacturing, CNC machining, and injection molding, to produce physical components with representative geometrical and mechanical properties.

█ Assembly and fit verification

Evaluation of dimensional accuracy, tolerances and ergonomic fit through the integration of fabricated components.

█ Functional validation

Testing the prototype under realistic operating conditions to assess performance and identify potential design deficiencies or areas for improvement.

█ Iterative refinement

Incorporation of design modifications based on experimental results, followed by successive prototyping cycles to progressively converge on an optimized and production-ready design.

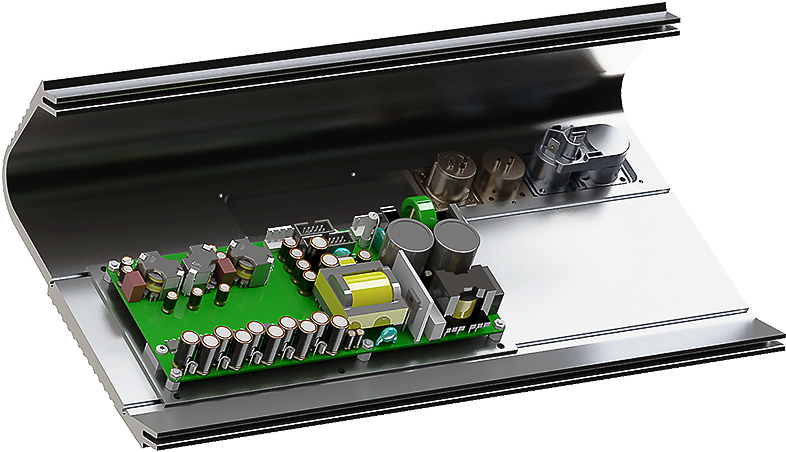

Before the physical prototyping begins, our industrial designers create a detailed three-dimensional (3D) digital model using MCAD platforms such as SolidWorks™ or Autodesk™ 3ds Max. These digital models serve both as precise design representations and as communication tools for stakeholders and potential users. While direct fabrication without prior digital modeling is possible, virtual modeling generally enhances design accuracy and facilitates early evaluation of key parameters.

Physical prototypes are frequently produced using additive manufacturing, in which successive layers of polymer material are deposited to form a tangible model. It is important to distinguish between materials used in additive manufacturing and those employed in production processes such as micro-injection molding (MIM). Whereas 3D-printed polymers tend to exhibit layered surface textures and relatively coarse tolerances, MIM components typically feature smoother finishes and tighter dimensional accuracy, often within a 10–100 micron range.

Following prototype fabrication, areas requiring further refinement are identified through testing and evaluation. To ensure robust validation, multiple iterations of the prototype are usually developed, enabling comparative testing and optimization. This iterative prototyping cycle is essential for achieving alignment among aesthetic, ergonomic, and functional requirements, ultimately supporting a smooth transition to a market-ready, production-grade electronic product.

With the prototype completed, the development process moves into the critical phase of testing and refinement, corresponding to the Design Verification and Validation (DV&V) stage defined in engineering development standards such as ISO 9001, IEC 60601, and IEEE 15288. This phase ensures that the design meets specified requirements, satisfies regulatory expectations and demonstrates readiness for controlled production.

Following prototype evaluation, the process proceeds to the fabrication of Pilot Production Units (commonly known as Testing Pilots). These units represent the first hardware produced using processes, materials, and tolerances closely aligned with those intended for mass manufacturing. Unlike early prototypes, which primarily explore form and function, pilot builds are designed to validate both product performance and production feasibility.

The objectives of the Testing Pilot phase are threefold:

1. Design validation

To confirm that the product meets user needs and performs as intended under representative operating conditions.

2. Process verification

To assess manufacturability, supply chain readiness, and process stability, enabling identification and mitigation of potential risks before full-scale production.

3. Risk identification and mitigation

To detect latent design flaws, reliability concerns, or regulatory compliance issues that may not have surfaced during laboratory prototyping.

Feedback from end users, structured testing protocols, and statistical analyses of pilot performance provide key evidence for iterative improvement. This feedback loop aligns with the continuous improvement principles outlined in ISO 9001:2015, ensuring that all design modifications are systematically documented and implemented.

Upon successful completion of pilot testing, a Production Manual (or equivalent manufacturing documentation) is finalized. This document serves as the definitive reference for large-scale production, detailing assembly procedures, quality assurance processes and compliance specifications.

By integrating the Testing Pilot phase into the development lifecycle, organizations ensure that the final product is optimized, fully validated and demonstrably ready for mass production.

Once the prototype has successfully completed verification and validation testing, and the corresponding Prototype Build Manual has been finalized, the development team advances to the preparation of the Manufacturing (Production) Manual. This document constitutes a core element of the production documentation set and functions as the authoritative reference for large-scale manufacturing.

The Production Manual systematically details the end-to-end manufacturing process, encompassing:

█ Process Flow Descriptions

A stepwise outline of all production stages, from PCB assembly and component soldering to final system integration and packaging.

█ Tooling and Fixtures

Specifications for required tools, test equipment, and custom-engineered jigs or fixtures developed by the team to ensure precision, repeatability and safety during assembly.

█ Assembly Procedures

Standard operating procedures (SOPs) and work instructions, supplemented with diagrams and exploded views, defining the correct sequence of tasks and acceptable tolerances.

█ Supplier and Sourcing Information

An approved vendor list (AVL) identifying qualified suppliers, their associated part numbers, and procurement requirements for all electronic, mechanical and packaging components.

█ Quality Control Measures

Integration of inspection checkpoints, in-circuit testing (ICT), and functional test procedures to guarantee compliance with performance specifications and regulatory requirements.

By consolidating this information into a structured framework, the Production Manual ensures that manufacturing can be conducted consistently, with controlled quality, and in compliance with relevant standards (e.g., ISO 9001, IPC-A-610 for electronics assembly). Moreover, it enables seamless knowledge transfer from the design team to the manufacturing floor, supporting scalability from pilot runs to full-scale production.

Once all stakeholders have formally approved the final as-built version of the product, the project transitions into the manufacturing and market introduction phase. At this stage, large-scale production begins in accordance with the finalized Production Manual and supporting quality assurance documentation.

In parallel, a comprehensive market launch strategy is developed and implemented to ensure the product’s successful entry into its target segment. This strategy typically includes targeted promotional campaigns, distribution planning, and stakeholder communication. In practice, marketing initiatives often commence ahead of the official product release to build anticipation, strengthen brand recognition and prepare the market for adoption once the product becomes available.

By synchronizing manufacturing readiness with market introduction activities, organizations can align production capacity, supply chain logistics and customer demand. This integrated approach minimizes launch risks, accelerates adoption, and facilitates a seamless transition from product development to full commercial deployment.

More Specifics...

The industrial and mechanical design behind high-end audio and automation systems goes far beyond a single-page overview. From thoughtful ergonomics and heat dissipation to premium materials, precision craftsmanship and vibration control - every detail impacts performance and aesthetics. Our approach balances durability, functionality and innovation. Curious about our design philosophy or specific mechanical challenges? Reach out by phone or email, we’d be happy to discuss your design issues / interests and share possible design or engineering solutions.

Measurable operational improvements

An analysis of the project results and underlying KPIs shows that 92% of our projects met their development timelines, an improvement compared to previous years. This indicates that the ongoing adjustments to process optimization and team integration are having a positive impact. We remain focused on further improving our working methods to ensure your product is delivered on schedule.

WITHIN DEADLINE

PROJECT TEAM

ENGINEERING